How Membrane Switches Are Used to Enhance Safety and Efficiency in Industrial Equipment

How Membrane Switches Are Used to Enhance Safety and Efficiency in Industrial Equipment

Blog Article

Why Membrane Layer Switches Over Are Essential for Resilient Control Solution

Membrane layer switches play a critical role in making sure the toughness and reliability of control systems across numerous markets. As we discover the diverse advantages of membrane layer buttons, it comes to be obvious that their significance goes beyond mere performance, influencing customer experience and functional efficiency.

Overview of Membrane Layer Buttons

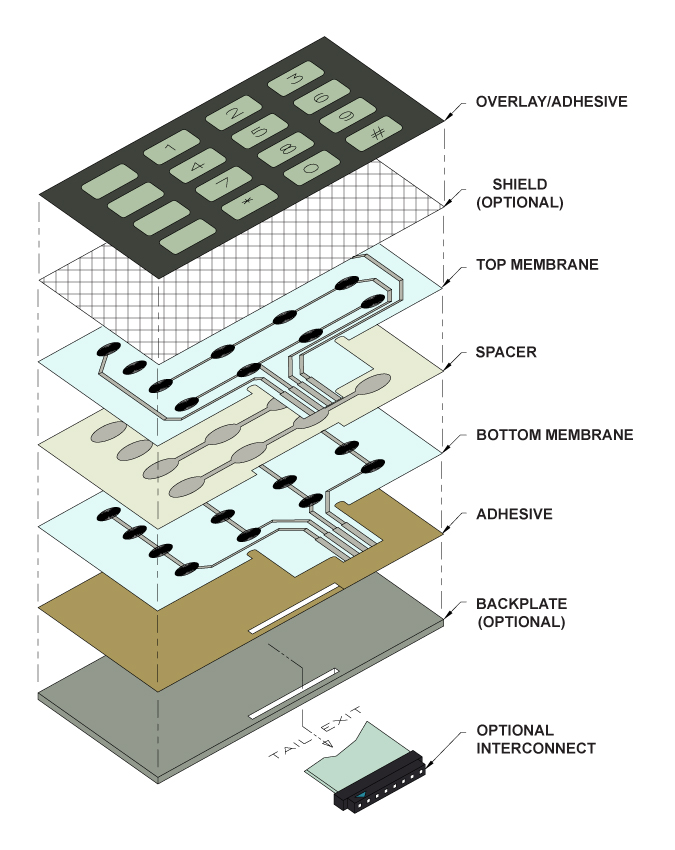

Membrane layer buttons are flexible and trusted parts generally used in different electronic control systems. These buttons are composed of several layers, consisting of a graphic overlay, a spacer layer, and a printed circuit layer. The graphic overlay supplies both functional and visual design, while the spacer layer ensures that the buttons are turned on just when pressed. The published circuit layer includes conductive traces that finish an electrical circuit when the membrane layer is pushed, allowing the tool to reply to customer inputs.

Membrane layer buttons are commonly favored in applications calling for a compact and light-weight style, making them ideal for handheld gadgets, clinical equipment, and industrial machinery. They can be personalized to satisfy details user demands and can integrate numerous features such as backlighting, tactile comments, and several shades. Membrane layer buttons are immune to dirt, dampness, and impurities, making them ideal for environments where resilience is necessary.

Benefits of Longevity

In several applications, the durability of membrane changes deals considerable benefits that boost their overall efficiency and reliability. These buttons are designed to stand up to rough settings, making them ideal for use sought after problems such as high moisture, extreme temperatures, and exposure to chemicals. Their durable building helps to stop damage from physical effect, making certain resilient functionality and reducing the need for frequent replacements.

Furthermore, membrane layer switches are immune to deterioration, which is crucial in applications where frequent interaction takes place. This longevity equates to lower upkeep costs, as companies take advantage of decreased downtime and less solution interruptions. The encapsulated layout of membrane layer changes secures inner parts from dirt and dampness access, additional adding to their life expectancy (membrane switch).

Another benefit is their capability to keep consistent performance in time. With a high resistance for mechanical tension, these switches maintain their tactile feedback and electrical stability, ensuring customer complete satisfaction. Ultimately, the longevity of membrane layer changes not just improves functional effectiveness yet likewise cultivates self-confidence in their dependability, making them a recommended choice for control systems throughout different fields.

Applications in Various Industries

Resilient control systems employing membrane switches locate comprehensive applications throughout a series of markets, each gaining from the one-of-a-kind qualities these switches provide. In the medical industry, membrane layer switches are crucial for gadgets such as client screens and analysis devices, where integrity and simplicity of cleaning are paramount. Their resistance to wetness and impurities ensures they keep capability in sterilized settings.

The vehicle market leverages membrane layer buttons for dashboard controls and infomercial systems, where they supply streamlined, inconspicuous user interfaces that enhance customer experience. These buttons are likewise description designed to withstand harsh problems, including exposure to severe temperature levels and vibrations.

In industrial settings, membrane buttons are typically utilized in machinery control panels, offering tactile feedback and sturdiness needed for high-usage applications. Their capability to withstand chemicals makes them appropriate for manufacturing environments where spills and contaminants are frequent.

Consumer electronic devices, such as kitchen devices and remotes, likewise use membrane buttons for their flexibility and cost-effectiveness. In general, the adaptability and durable nature of membrane switches make them indispensable throughout different industries, ensuring reliable procedure and durability in control systems.

Layout and Visual Appeal

While capability is paramount, the style and aesthetic appeal of control systems outfitted with membrane buttons play an important role in customer involvement and general experience (membrane switch). The aesthetic layout of these switches can dramatically affect individual understanding and interaction. A well-designed membrane button boosts the attractiveness of the device, making it extra enticing to users and cultivating a link between the individual and the item

Membrane layer changes provide a fantastic deal of versatility in style, enabling makers to tailor graphics, shades, and appearances to align with brand name identity and product aesthetics. Using vibrant shades and unique patterns can attract interest, while responsive feedback can reinforce the user's communication with the device. In addition, the capability to incorporate LED indicators and backlighting into the membrane switch design supplies both functional and visual benefits, enhancing presence and use in different settings.

Enhancing User Experience

Additionally, membrane buttons can be tailored to integrate graphical interfaces, improving use by providing info in a clear and instinctive fashion (membrane switch). This customization can include icons, labels, and shade coding that guide customers with complex functionalities effortlessly. Additionally, their versatility enables for assimilation in various environments, making sure constant performance whether in industrial equipment or customer electronic devices

The sturdiness of membrane switches likewise plays an important duty in customer experience. By holding up against harsh conditions and extended use, these buttons lower the possibility of system failings, thus promoting reliability and customer confidence. Ultimately, the tactical usage of membrane layer switches not only boosts performance but likewise considerably improves individual interaction with control systems, making them an essential component in modern style.

Final Thought

Report this page